How tech will remodel factories

A robotic arm will get to work at German producer Rittal’s good manufacturing unit in Haiger, to the west of Hesse, Germany.

Rittal

Conversational synthetic intelligence that can be utilized to speak with tools and generate machine components. Digital variations of automobiles and planes that may be modified to fine-tune their bodily counterparts. And autonomous robots that transfer as you stroll by.

These are only a few of the applied sciences that can energy the factories of the longer term, in keeping with technologists and trade consultants who spoke with CNBC.

Sooner or later, factories can be way more linked, counting on a mixture of applied sciences, from synthetic intelligence, knowledge platforms and edge gadgets to the cloud, robotics and sensors, Goetz Erhardt, Europe lead for Accenture’s digital engineering and manufacturing division, informed CNBC.

“These applied sciences help absolutely automated, ‘darkish’ vegetation, automated decision-making, enhanced tools monitoring, and new manufacturing networks with recycling and upcycling capabilities,” Erhardt stated through electronic mail.

At this time’s factories — from these utilized in equipment and cars to meals processing vegetation — have progressively turn into extra superior with regard to adopting expertise. Robotic arms concerned within the manufacturing course of — including and eradicating supplies, welding and putting items on pallets — are actually a standard sight.

Extra superior A.I.

As way more superior synthetic intelligence applied sciences are added into the combo, the commercial manufacturing course of may shake up additional. Conversational techniques reminiscent of OpenAI’s GPT may in the future turn into built-in into robotics, enabling extra refined, emotionally clever machines.

“Generative AI (AI that makes new content material in response to person inputs) has huge potential in manufacturing for tools optimization, interplay and intelligence — from robotic processes by way of to machining,” Simon Floyd, director of producing and transportation industries at Google Cloud, informed CNBC.

Google is among the many tech world giants seeking to capitalize on giant language fashions, which may generate extra humanlike responses due to the massive quantities of knowledge they’re educated on. The corporate launched its personal AI chatbot Bard earlier this yr to rival OpenAI’s ChatGPT.

Client merchandise aren’t the one focus of Google’s AI efforts. The corporate just lately upgraded its cloud platform for producers to extra effectively pull knowledge from machines and detect anomalies within the manufacturing course of.

Going ahead, AI will be capable of “converse utilizing pure language with manufacturing tools to know the present state and the expected future efficiency — due to this fact helping individuals and permitting them to deal with excessive worth duties,” Google Cloud’s Floyd informed CNBC.

Floyd stated that Google is already working to realize this with pure language processing capabilities in its AI instruments. The corporate has additionally created a language mannequin for robots known as PaLM-E, which gathers sensory info from the bodily atmosphere, in addition to text-based inputs.

Engineers will finally be capable of develop new equipment utilizing generative AI instruments, Floyd stated.

“Sooner or later, there may be potential to generate content material from and for a lot of sorts of manufacturing tools, starting from particular restore directions to software program code that’s tailor-made to a selected asset.”

‘Digital twins’

One improvement many industrialists are enthusiastic about is “digital twins” — 3D digital replicas of objects within the bodily world that may be modified and up to date in parallel with the gadgets they purpose to imitate.

One instance of an organization utilizing digital twins to assist its bodily manufacturing is Rolls Royce, whose engineers create exact digital copies of its jet engines after which set up sensors and satellite tv for pc networks on-board to feed again knowledge to the digital copy in actual time.

“For each trendy Rolls Royce jet engine up on a aircraft within the sky, there’s one within the cyber sphere that must be maintained, figuring out how a lot stress goes by way of the aircraft,” stated John Hill, CEO of Silico AI, a startup that focuses on digital twins for enterprise processes. “That may depend upon how the engine is faring within the atmospheric situations and pressures within the air.”

One other instance is Renault, which created a digital twin for a brand new “software-defined” automobile with synthetic intelligence capabilities to boost companies.

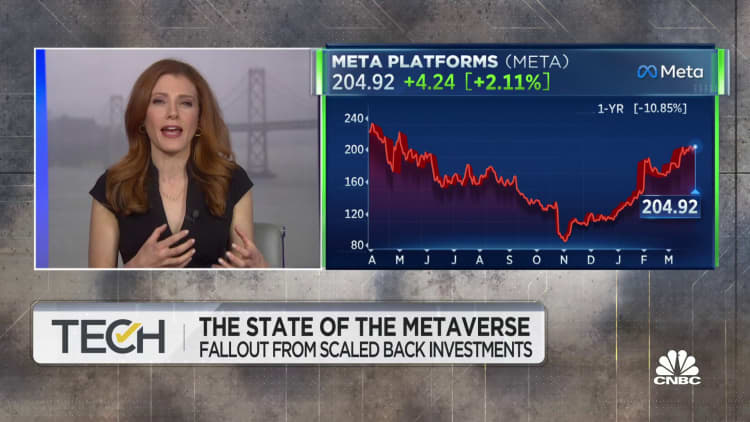

Digital twins type a part of the so-called “metaverse,” which embodies the concept that individuals will spend extra of their work and leisure time in enormous 3D digital areas. Some corporations are additionally seeking to incorporate the bodily world in some iterations of the metaverse.

Many producers see potential within the “industrial metaverse,” a model of the metaverse tailor-made to the manufacturing, building and engineering industries. Accenture’s Erhardt informed CNBC that he’s primarily seeing use circumstances in inventive collaboration and product improvement, upkeep and distant repairs, designing and optimizing manufacturing operations, and workforce coaching

“The metaverse may turn into a sport changer for industrial corporations as soon as they couple its collaborative, immersive, visible and intuitive dimensions with digital twins fed by built-in knowledge swimming pools throughout departments, techniques, operations expertise and IT,” Erhardt stated. “This might create a digital, absolutely immersive and intuitive simulation of the complete enterprise.”

Security first

Corporations are searching for methods to chop down on extra menial duties in factories with digital expertise, amid a wave of labor shortages.

“Beforehand, automation has not been an possibility for manufacturing merchandise because of minimal monetary assets and funding,” Olivier Ribet, Govt Vice President, EMEAR at Dassault Systèmes, informed CNBC.

“Nonetheless, that is altering quickly because of technological adjustments which have decreased prices and democratized automation by way of low/no code robotics permitting extra manufacturing corporations to leverage the benefits of automation by way of precision, effectivity, and productiveness.”

There are downsides to think about — not least of which job safety — because the rise of AI and digital automation in factories has led to worries in regards to the labor market. Generative AI, a comparatively latest improvement, may erase 300 million jobs, Goldman Sachs estimates.

Nonetheless, historical past reveals that technological progress would not simply make jobs redundant, it additionally creates new roles— which generally outpaces the variety of jobs displaced. Producers are nonetheless scrambling for workers, with 41% of producing companies citing expertise pool as a “very vital” barrier stopping full potential, in keeping with a Bain and Firm survey.

The hope is that connecting machines to the web and integrating sensors and predictive AI algorithms will permit them to extra safely navigate their environment and work collaboratively with people, relatively than substitute them, in keeping with Maya Pindeus, CEO of AI startup Humanising Autonomy.

“Consider the manufacturing unit, you might have robotic arms, you might have completely different automobiles to maneuver items round, you might have operators, you might have security cameras,” Pindeus informed CNBC.

“What I’d take a look at within the manufacturing unit of the longer term is you might have excessive ranges of protected automation that may function round individuals … I have been to factories the place you might have the massive robotic arm caged up and it is actually distant from individuals. It seems to be very inefficient to me.”

.jpg)